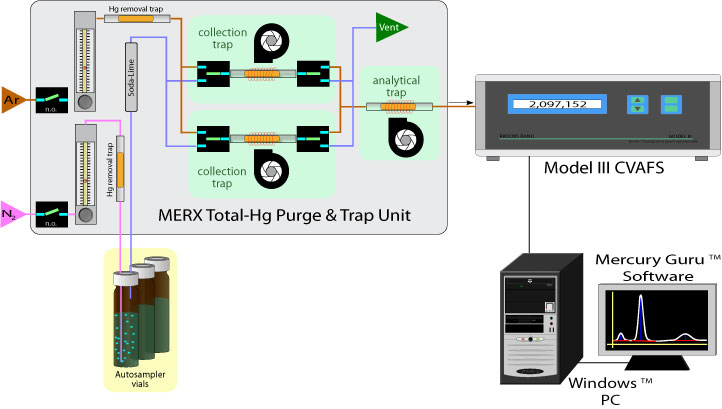

Automated Mercury System

MERX-T

At Brooks Rand, we firmly believe that obtaining the highest quality data is essential, but we also recognize the necessity of operational efficiency. Our decades of trace-level mercury analysis experience have enabled us to develop a system that achieves both of these critical goals.